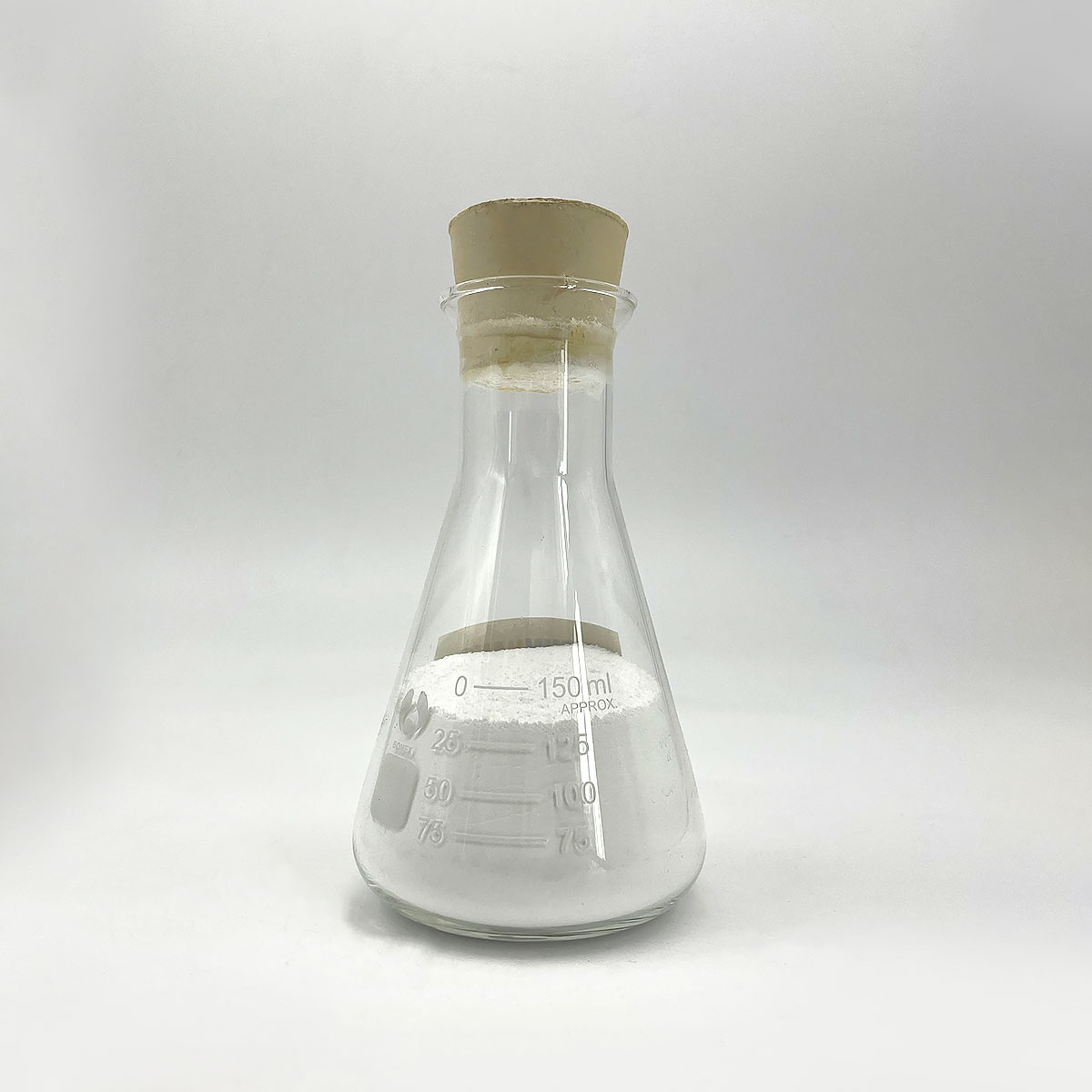

BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer

Polycarboxylate water reducer, as a representative of high-performance concrete additives, has excellent dispersibility, high water reduction rate and environmental friendliness.

Description

(BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer)

Parameter of BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer

The BRD 431 factory concrete mortar adhesive market is projected to reach $50 billion by 2029, with an annual growth rate of 8%. The major players in the market include Priceline andBRD International. BRD is known for its innovative advanced adhesives and immersible adhesive technology that offers superior performance and durability compared to other materials.

Parameters of BRD factory concrete mortar adhesive

1. Porosity: The recommended porosity of the ready-mix concrete should be less than 1% due to factors such as increasing cement quantity, adding water, or changing temperature, which can affect the ability to bond properly.

2. Concrete type: Brd AAC Mortar adhesives are widely used for producing instant concrete (IAC) and dry mix concrete (DMC). These types of have different strengths and requirements depending on the application, so the preference for the chosen adhesives would depend on the specific material.

3. grade: The grade used for the manufacturing of concrete needs to be appropriate for the intended use case. For example, brd AAC Mortar is commonly used for domestic construction but may require higher grades in commercial applications due to its higher load-bearing capacity.

4. Addition of water: A reasonable amount of water should be added to the concrete mixture to ensure proper mixing and bonding of the cement, aggregate, and other components.

5. Additives: Brd AAC Mortar admimentos often contain a variety of additives such as vessels, plasticizers, fillers, antioxidants, etc., to enhance the adhesivity, compatibility, and durability of the concrete.

6. Adsorbent: Adispersants used in the BRD factory concrete mortar adhesive can also impact the final consistency and appearance of the concrete. For instance, water, silicone, and other additives can improve the flowability and set density of the concrete, making it easier to pour, seal, and protect it from moisture and environmental conditions.

7. method: The preferred method depends on the application’s purpose and complexity. The majority of use the mixed Concrete Production System (MCS) where a liquid concrete paste is poured onto a pre-existing concrete mix during a pouring operation. Other methods like dry casting, continuous casting, or beam casting involve additional steps such as casting, cutting, and/or tapping to obtain more precise and controlled results.

Overall, while not all concrete mortars provide identical specifications, it is important to choose a product that aligns with the specific requirements and specifications of the project and meets the performance standards required for your project.

(BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer)

Company Profile

Foamed Concrete Services is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality concrete additives and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality concrete materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

Application of BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer

High-rise buildings and infrastructure: widely used in large-scale buildings and bridge projects that require high strength and durability.

Prestressed concrete and precast components: Improve the fluidity and early strength of concrete to facilitate the production of precast components.

Large-volume concrete construction: effectively control temperature rise and reduce cracks, suitable for large-volume concrete pouring in hydropower stations, nuclear power plants, etc.

Repair and reinforcement projects: In the repair of old concrete structures, improve the bonding strength of the interface between new and old concrete.

Special environmental engineering: In harsh environments such as offshore engineering and saline-alkali land, its corrosion resistance can be used to improve the durability of concrete.

5 FAQs about BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer

Q: Does BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer affect the color of concrete?

Answer: Normally, polycarboxylate superplasticizer will not change the natural color of concrete.

Q: What is the recommended dosage of BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer?

Answer: The addition amount is generally 0.15% to 0.4% of the cement weight, which is adjusted according to the concrete mix ratio and performance requirements.

Q: Can using BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer extend the setting time of concrete?

Answer: Some polycarboxylate superplasticizers contain retardant components, which can moderately adjust the setting time, but not all products have this effect.

Q: Is BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer suitable for all types of cement?

Answer: BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer has a wide range of cement adaptability, but different cements may need to adjust the type or amount of superplasticizer to achieve the best effect.

Q: Does BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer have any effect on the shrinkage of concrete?

Answer: Appropriate use usually does not significantly increase the shrinkage of concrete, but excessive water reduction may slightly increase drying shrinkage. Pay attention to the balance of the formula.

(BRD Factory Concrete Mortar Admixture Concrete Polycarboxylic acid superplasticizer)