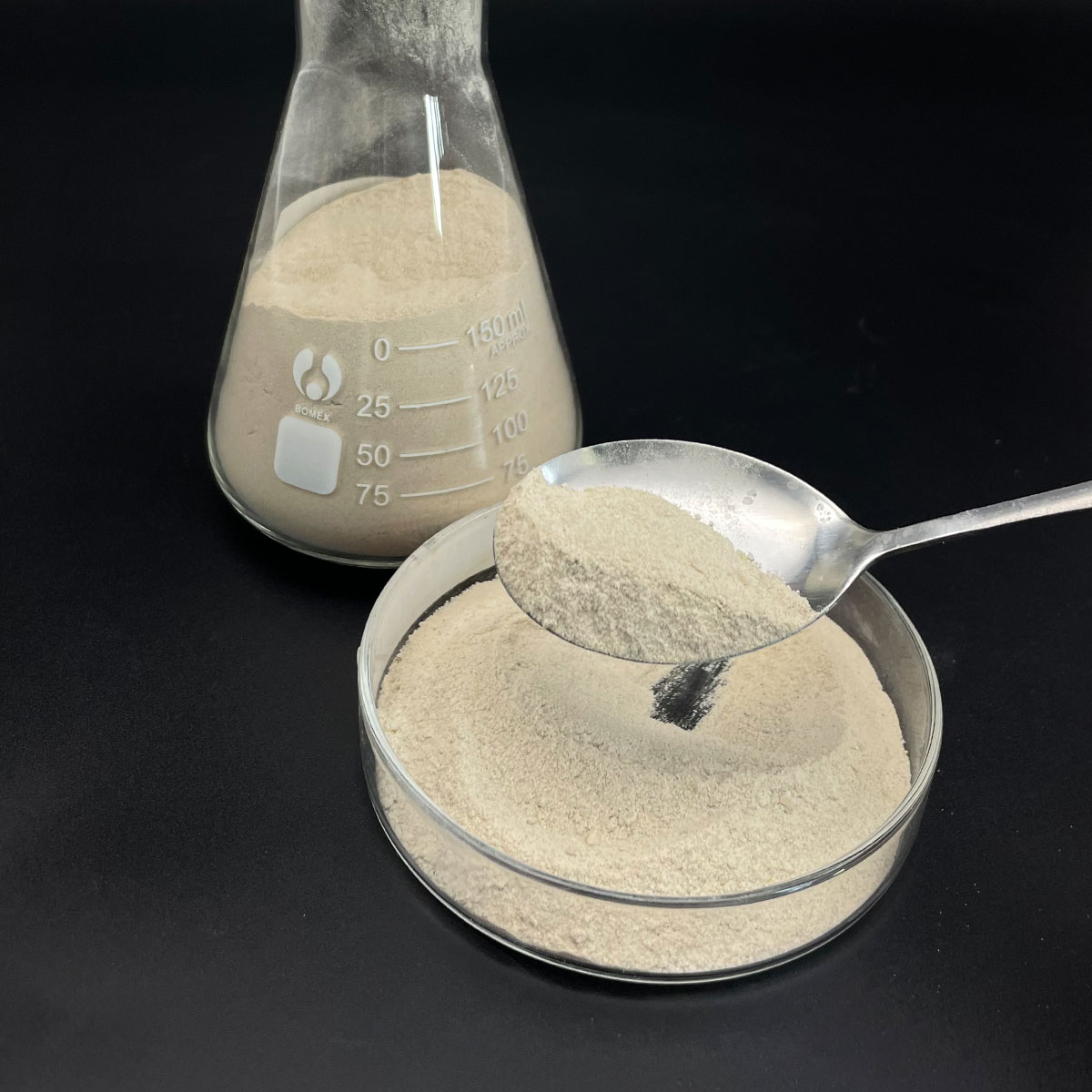

98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer

Concrete water reducer, as a key additive to improve concrete performance, effectively enhances the strength, durability and construction convenience of concrete by reducing the amount of mixing water without reducing workability.

Description

Introduction of 98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer

Concrete water reducer, also known as plasticizer or dispersant to some extent, is a chemical substance added during the concrete mixing process. Its main function is to reduce the amount of water required in the concrete mixture while maintaining or improving the workability (fluidity, cohesion) of the concrete. By reducing the water-cement ratio, water reducer can improve the performance and durability of concrete without sacrificing its strength. It is one of the indispensable additives in modern concrete technology.

Features of 98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer

Improved fluidity: Even with reduced water consumption, the fluidity and pumpability of concrete can be significantly increased, making construction operations easier.

Enhanced strength: By reducing the water-cement ratio, the early and late strength of concrete is increased, and the durability and load-bearing capacity of the structure are enhanced.

Improve durability: reduce porosity, improve concrete’s impermeability, freeze-thaw resistance and chemical erosion resistance, and extend service life.

Cost savings: Reduce cement consumption, lower overall costs, and improve construction efficiency.

Environmental protection and energy saving: reducing the use of water and cement is beneficial to environmental protection, energy saving and emission reduction.

Wide applicability: Suitable for a variety of concrete projects, including ready-mixed concrete, pumped concrete, high-performance concrete, etc.

(98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer)

Parameter of 98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer

Polycarboxylate Superplasticizer (PCE) Powder, with an impressive 98% content, is a crucial ingredient in the preparation of high-performance concrete. This advanced additive significantly improves the workability and reduces the water demand of concrete mixes without compromising on strength or durability.

The 98% content refers to the concentration of the active polycarboxylate polymers within the PCE powder. These polymers, when dissolved in water, form a network that coats the surface of cement particles, effectively reducing their inter-particle friction. This leads to a significant increase in workability, allowing for easier handling and pouring of the concrete mix, while also enabling a reduction in water content without affecting the concrete’s strength.

One of the primary benefits of using a 98% content PCE powder is its ability to enhance the compressive strength and durability of the final concrete product. By improving the hydration process of cement, these superplasticizers promote better bonding between cement particles, resulting in stronger and more resilient structures. Additionally, they help in minimizing the formation of micro-cracks, thus enhancing the overall durability of the concrete.

In terms of sustainability, the use of high-concentration PCE powders like this one can lead to reduced carbon emissions. By decreasing the water content required for mixing, it minimizes the energy consumption associated with water heating during the concrete production process. This not only reduces environmental impact but also lowers operational costs for construction projects.

Furthermore, these superplasticizers offer enhanced rheological properties, which are crucial for achieving uniform and consistent concrete placement. They enable the concrete to flow freely, ensuring that all components are properly distributed throughout the mix, leading to a more homogenous and structurally sound end product.

In conclusion, the 98% content polycarboxylate superplasticizer powder offers a multitude of advantages in concrete applications. Its high concentration ensures efficient and effective performance, leading to improved workability, enhanced strength and durability, reduced environmental impact, and optimized operational costs. As such, it represents a valuable investment for any construction project aiming to achieve superior concrete quality and efficiency.

(98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer)

Company Profile

Foamed Concrete Services is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality concrete additives and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality concrete materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

Applications of 98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer

Building construction: construction of large infrastructure such as high-rise buildings, bridges, and tunnels to improve construction quality and efficiency.

Prefabricated components: production of high-quality prefabricated panels, beams, columns, etc., to facilitate standardized production and installation.

Road engineering: improve the crack resistance and wear resistance of road concrete and extend the service life of roads.

Repair and reinforcement: in the repair and reinforcement of old concrete structures, improve the bond between new and old concrete.

Special concrete: such as self-compacting concrete, plain concrete, etc., application scenarios that require high fluidity and surface finish.

5 FAQs for 98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer

Q: Will 98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer change the color of concrete?

A: Generally, water reducers do not affect the natural color of concrete. However, it is recommended to conduct a small-scale test to confirm before formal use.

Q: How much 98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer should be added?

A: The addition amount is generally 0.2% to 2% of the weight of cement, depending on the concrete formula and the desired effect. You should refer to the product instructions or consult professionals.

Q: Can all types of concrete use water reducers?

A: Almost all concrete can benefit from the use of water reducers, but for specific applications (such as projects with high durability requirements), specific types of water reducers should be selected.

Q: Will 98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer affect the setting time of concrete?

A: Some water reducers may affect the setting time, some can delay setting, and some have no obvious effect. Depending on the needs, composite water reducers with the function of adjusting the setting time can also be selected.

Q: Is it necessary to maintain after using 98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer?

A: Yes, although 98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer can improve the performance of concrete, normal maintenance procedures are still necessary to ensure that concrete achieves optimal performance.

(98% content polycarboxylate superplasticizer PCE powder for concrete super plasticizer)