best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder

Hydroxypropyl Methylcellulose (HPMC) is a high-performance multifunctional additive that plays an irreplaceable role in many industries such as construction, medicine, and food.

Description

Introduction to best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder

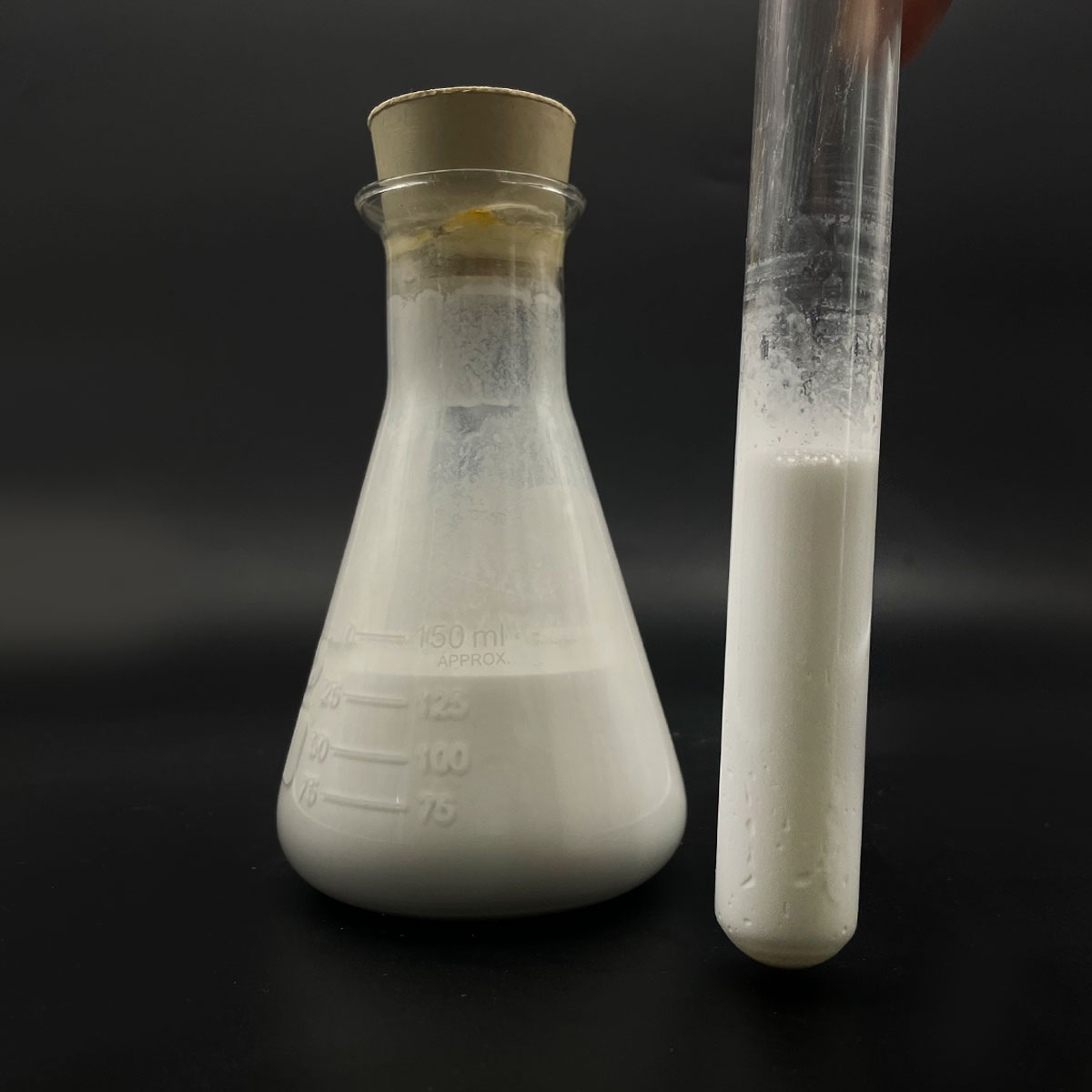

Hydroxypropyl Methylcellulose (HPMC), whose Chinese name is hydroxypropyl methylcellulose, is a semi-synthetic, non-ionic cellulose ether obtained by chemically modifying natural cellulose. This white powder can form a transparent viscous solution after dissolving in water. It has excellent thickening, water retention, stability and film-forming properties. It is an indispensable multifunctional additive in many fields such as construction, medicine, and food.

Characteristics and advantages of best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder

Excellent water solubility: It can be quickly dissolved in cold water to form a clear and stable solution.

Efficient thickening and water retention ability: Increase the viscosity of the material, effectively reduce water evaporation, and improve work efficiency.

Good stability: It has good stability to acids, alkalis, and salts, and is suitable for a wide range of pH values.

Film-forming and protective effects: After drying, it forms a tough and transparent film to protect the substrate and prevent water penetration and evaporation.

Non-toxic and non-irritating: It has good biocompatibility and is suitable for the fields of medicine and food.

Adjustability: By changing the degree of substitution and molecular weight, its performance can be adjusted to meet different application requirements.

(best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder)

Parameter of best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder

The HPMC (high molecular polypropylene) used in mortar binder ceramic tile glue putty powder is known for its ability to form strong and durable bonding bonds with materials. This property is particularly useful in the application of mortar bond cement paste, which provides excellent grip and stability to various surfaces.

One of the key advantages of using HPMC in this context is that it can withstand high temperatures and pressures, making it ideal for use in applications where durability and longevity are crucial. Additionally, HPMC’s high mechanical strength makes it suitable for applications such as sealants, adhesives, and sealants. Overall, HPMC offers an attractive option for builders looking to improve the performance of their mortar binder ceramic tile glue putty powder.

(best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder)

Company Profile

Foamed Concrete Services is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality concrete additives and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality concrete materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

Application of best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder

Construction industry: As an additive for cement mortar, it improves the construction performance of tile adhesive, putty powder, self-leveling mortar, etc.

Pharmaceutical industry: Used as tablet coating material, adhesive, disintegrant to improve the stability and release characteristics of drugs.

Food industry: As a stabilizer, thickener and film former, it is used in ice cream, jam, baked goods, etc.

Cosmetics industry: As a thickener and film former, it is used in products such as lotions, creams, shampoos, etc. to enhance the texture of products.

Textile and papermaking industry: As a sizing agent and sizing agent, it improves the processing performance of fibers and the quality of paper.

5 FAQs of best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder

Q: Is best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder harmful to the human body?

A: best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder is non-toxic and widely used in the fields of medicine and food with high safety.

Q: What is the main role of best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder in building mortar?

A: It mainly increases the water retention and workability of mortar, reduces shrinkage cracks, and improves bonding strength.

Q: What is the solubility of best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder at different temperatures?

A: best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder can be dissolved in cold water, but the dissolution speed increases with the temperature, and it dissolves more completely at high temperature.

Q: How to choose the right best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder model for a specific application?

A: It is necessary to select products with appropriate degree of substitution and molecular weight based on factors such as application area, required viscosity, water retention, and dissolution speed.

Q: Are there any restrictions on the use of best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder in food?

A: best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder has been approved for use as a food additive in many countries, but it still needs to comply with food safety regulations and limit standards in various regions.

(best-ing of hpmc/rdp/starch ether HPMC used in mortar binder ceramic tile glue putty powder)