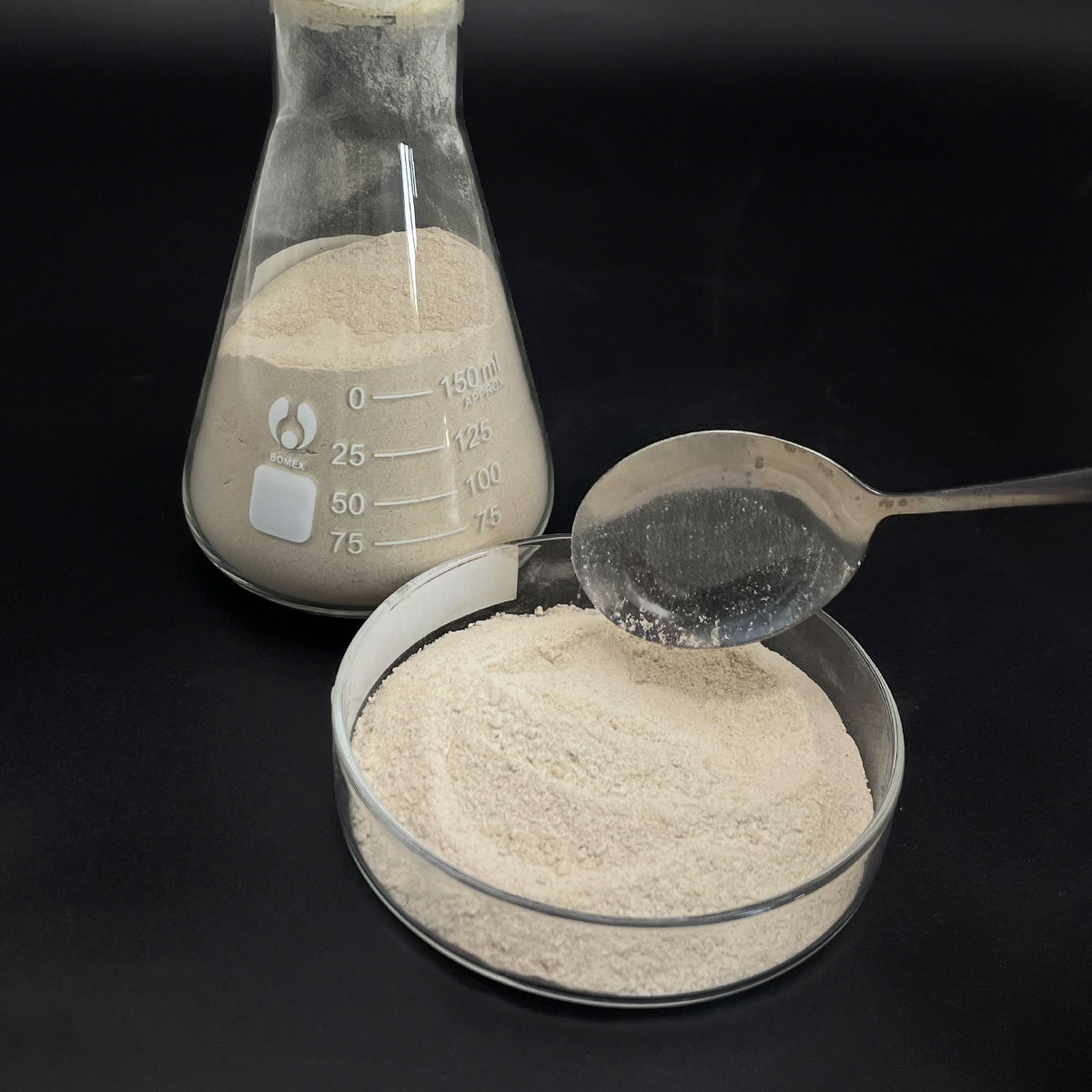

Redispersible Polymer powder RDP/VAE

Redispersible Polymer Powder is an innovative building material additive derived from advanced spray drying technology that can significantly improve the overall performance of mortar and concrete.

Description

Introduce of Redispersible Polymer powder RDP/VAE

Redispersible Polymer Powder (RDP), also known as redispersible latex powder, is a powdered polymer formed by spray drying of polymer emulsion. This powder can be dispersed again to form a stable emulsion after contacting water. It is widely used in construction chemicals such as dry-mix mortars, tile adhesives, plastering mortars, and self-leveling floor materials to enhance the adhesion, waterproofness, and Flexibility and durability.

Features of Redispersible Polymer powder RDP/VAE

Enhanced bonding force: Significantly improve the bonding strength between mortar and other base materials, reducing hollowing and falling off.

Improve flexibility: Give cement-based materials better stretchability and crack resistance, effectively resisting cracking caused by temperature changes and vibration.

Improve durability: Enhance the material’s impermeability, freeze-thaw resistance and chemical corrosion resistance to extend its service life.

Easy construction: Improve the plasticity and opening time of mortar to facilitate construction operations and adjustments.

Environmental protection: no solvent evaporation, meets environmental protection requirements, and is suitable for green building construction.

Good compatibility: Compatible with a variety of cement-based materials and can be widely used in different types of building materials.

(Redispersible Polymer powder RDP/VAE)

Parameter of Redispersible Polymer powder RDP/VAE

Redispersible polymer powder (RDP) and VAE parameters refer to the quantities of each material used in a polymer-based matrix. The quantities can vary depending on various factors such as production conditions, intended use, and materials.

Here are some commonly used parameters for RDP:

1. Powder: This parameter determines the diameter of the that are mixed into the matrix. A higher particle size will result in a smaller particle volume but a larger aggregate.

2. Volume modulus: This parameter describes the strength of the polymer matrix. It ranges from 0 to 100 GPa and is typically calculated using the Young’s modulus or modulus of the material.

3. Cross-reaction ratio: This parameter measures how well the particles within the matrix interact with each other during deformation. A higher cross-reaction ratio results in more continuous, consistent deformation throughout the matrix.

4. Shapememory: This parameter affects the capacity of the matrix to remember its shape after deformation. A higher shape memory will result in better mechanical properties and more consistent deformation throughout the matrix.

5.دة time: This parameter is used to control the aging rate of the matrix. A longerدة time will result in stronger overall tensile strength, while a shorter day-to-day rate will result in weaker mechanical properties.

6. Discrimination rate: This parameter measures the rate at which the matrix changes shape due to deformation. A higher discrimination rate will result in stronger overall tensile strength, while a lower value may lead to weaker mechanical properties.

Overall, these parameters play an important role in determining the strength and performance of the RDP and VAE matrices. Choosing the appropriate values for each parameter can help improve the consistency and stability of the matrix during deformation.

(Redispersible Polymer powder RDP/VAE)

Company Profile

Foamed Concrete Services is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality concrete additives and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality concrete materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

Application of Redispersible Polymer powder RDP/VAE

Tile adhesive: Improve the firmness and durability of ceramic tiles and prevent hollowing and falling off.

Exterior wall insulation system: used as an additive in bonding mortar and plastering mortar to enhance the overall waterproof and crack-resistant performance of the system.

Self-leveling floor: Used for self-leveling floor materials to improve the flatness, wear resistance and compressive strength of the ground.

Repair mortar: It is used to increase the adhesion and durability of repair materials and is suitable for repairing various structures.

Waterproof mortar: Enhance the waterproof performance of mortar, used for waterproofing projects such as basements and pools.

5 FAQs for Redispersible Polymer powder RDP/VAE

Q: Does Redispersible Polymer powder RDP/VAE require special treatment before use?

Answer: No special treatment is required. Just add Redispersible Polymer powder RDP/VAE to the dry-mixed mortar in the recommended proportion and redisperse it when adding water and stirring.

Q: Is Redispersible Polymer powder RDP/VAE sensitive to environmental conditions?

A: Yes, although Redispersible Polymer powder RDP/VAE itself is stable, moisture and high temperatures should be avoided during storage to avoid affecting its performance.

Q: Is Redispersible Polymer powder RDP/VAE suitable for all types of cement?

Answer: Redispersible Polymer powder RDP/VAE has good versatility, but for different types of cement and applications, the model or addition amount may need to be adjusted to achieve the best effect.

Q: What properties of mortar can Redispersible Polymer powder RDP/VAE significantly improve?

Answer: It mainly improves adhesion, flexibility, water resistance and durability, while improving construction performance.

Q: Does Redispersible Polymer powder RDP/VAE have a negative impact on the environment?

Answer: Redispersible Polymer powder RDP/VAE is a water-based product. No harmful solvents are released during use, and it is relatively environmentally friendly. However, the waste after use should be disposed of in accordance with local environmental protection regulations.

(Redispersible Polymer powder RDP/VAE)