special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals

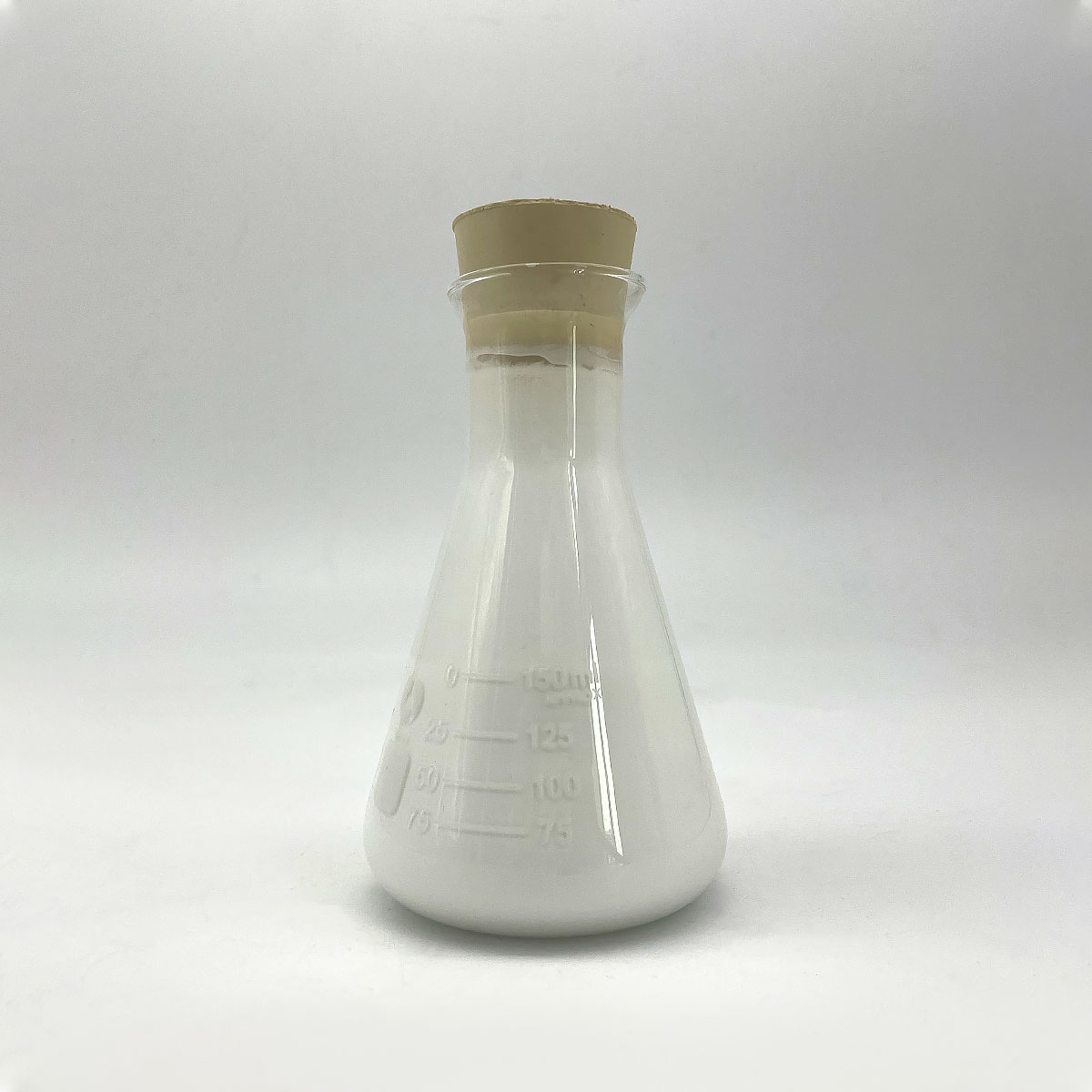

Redispersible Polymer Powder is an innovative building material additive derived from advanced spray drying technology that can significantly improve the overall performance of mortar and concrete.

Description

Introduce of special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals

Redispersible Polymer Powder (RDP), also known as redispersible latex powder, is a powdered polymer formed by spray drying of polymer emulsion. This powder can be dispersed again to form a stable emulsion after contacting water. It is widely used in construction chemicals such as dry-mix mortars, tile adhesives, plastering mortars, and self-leveling floor materials to enhance the adhesion, waterproofness, and Flexibility and durability.

Features of special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals

Enhanced bonding force: Significantly improve the bonding strength between mortar and other base materials, reducing hollowing and falling off.

Improve flexibility: Give cement-based materials better stretchability and crack resistance, effectively resisting cracking caused by temperature changes and vibration.

Improve durability: Enhance the material’s impermeability, freeze-thaw resistance and chemical corrosion resistance to extend its service life.

Easy construction: Improve the plasticity and opening time of mortar to facilitate construction operations and adjustments.

Environmental protection: no solvent evaporation, meets environmental protection requirements, and is suitable for green building construction.

Good compatibility: Compatible with a variety of cement-based materials and can be widely used in different types of building materials.

(special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals)

Parameter of special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals

Special mortar is an advanced technique used to create high-quality paste-based fillings for various construction applications such as floors, walls, and doors. It involves the use of a combination of special mortar components, including a specialized mixture of materials, an added layer of films, and a mix of paints and varnishes.

One of the key benefits of using special mortar is its ability to provide better bond strength and durability than traditional mortar systems. This is because special mortar materials have been specifically designed to integrate seamlessly with building materials, improving their compatibility and offering longer-lasting results.

To achieve these benefits, a wide range of binders and films can be incorporated into special mortar. The choice of binder and film will depend on the specific application requirements and desired outcome. For example, a binder made from a variety of polymers, such as polyurethane or glass fiber, can provide excellent adhesion to the surface of the concrete floor.

In addition to binders, special mortar also includes paints and varnishes. These powders and sprays are carefully applied to the joints in special mortar to ensure that they meet the required quality standards. They not only provide a visual improvement but also help to prevent fungal growth and ensure that the joint is properly sealed.

Overall, special mortar offers numerous advantages over traditional mortar systems, including improved bond strength, greater flexibility and compatibility, and better paint and varnish performance. Its versatility and adaptability make it a popular choice for many construction applications, from domestic to commercial projects.

(special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals)

Company Profile

Foamed Concrete Services is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality concrete additives and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality concrete materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

Application of special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals

Tile adhesive: Improve the firmness and durability of ceramic tiles and prevent hollowing and falling off.

Exterior wall insulation system: used as an additive in bonding mortar and plastering mortar to enhance the overall waterproof and crack-resistant performance of the system.

Self-leveling floor: Used for self-leveling floor materials to improve the flatness, wear resistance and compressive strength of the ground.

Repair mortar: It is used to increase the adhesion and durability of repair materials and is suitable for repairing various structures.

Waterproof mortar: Enhance the waterproof performance of mortar, used for waterproofing projects such as basements and pools.

5 FAQs for special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals

Q: Does special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals require special treatment before use?

Answer: No special treatment is required. Just add special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals to the dry-mixed mortar in the recommended proportion and redisperse it when adding water and stirring.

Q: Is special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals sensitive to environmental conditions?

A: Yes, although special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals itself is stable, moisture and high temperatures should be avoided during storage to avoid affecting its performance.

Q: Is special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals suitable for all types of cement?

Answer: special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals has good versatility, but for different types of cement and applications, the model or addition amount may need to be adjusted to achieve the best effect.

Q: What properties of mortar can special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals significantly improve?

Answer: It mainly improves adhesion, flexibility, water resistance and durability, while improving construction performance.

Q: Does special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals have a negative impact on the environment?

Answer: special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals is a water-based product. No harmful solvents are released during use, and it is relatively environmentally friendly. However, the waste after use should be disposed of in accordance with local environmental protection regulations.

(special mortar uses Good Film Formation tape joint compounds Redispersible Polymer Powder RDP Skim coat Chemicals)