Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam

Foamed concrete, also known as lightweight concrete or foamed concrete, is a lightweight porous building material made of cement, water, fine aggregate, and air or other gases.

Description

Introduction to Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam

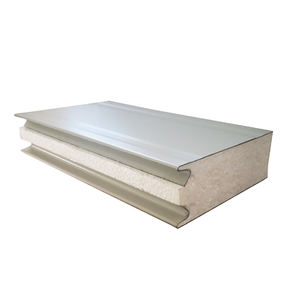

Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam , also known as cellular lightweight concrete or aerated concrete, is an innovative building material that has gained significant attention in the construction industry for its unique properties and versatility. This lightweight, porous concrete is formed by introducing air or gas bubbles into a cement-based mixture, creating a low-density, highly insulating, and easy-to-work-with material. Its advent has opened up new possibilities in construction, from insulation and filling applications to entire building systems, offering an efficient and sustainable alternative to traditional concrete.

Features of Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam

Excellent Insulation Properties: The presence of air pockets within the material gives Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam superior thermal insulation capabilities, reducing heat transfer and providing an effective barrier against both cold and heat. This results in energy-efficient buildings with reduced heating and cooling requirements.

Good Sound Absorption: Alongside thermal insulation, Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam also excels in sound insulation due to its porous structure, which dampens noise transmission. It is particularly useful in buildings requiring high acoustic performance, such as theaters, schools, and hospitals.

Fire Resistance: Being primarily composed of inorganic materials, Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam possesses excellent fire-resistant properties, making it a safe choice for structures where fire safety is a priority.

Low Density and Lightweight: One of the standout features of Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam is its significantly lower density compared to standard concrete, typically ranging from 400 to 1600 kg/m³. This reduction in weight makes it easier to transport, handle, and install, reducing the need for heavy machinery and potentially lowering construction costs.

Workability and Pumpability: The fluid nature of Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam allows it to be easily pumped over long distances and into tight or hard-to-reach spaces, facilitating its use in a variety of applications, including filling voids, tunnel linings, and floor screeds.

(Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam )

Parameter of Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam

The Whole Building Concrete Crack Filler Expansion Polyurethane spray foam Insulation Liquid is a type of insulation foam that can be applied to concrete surfaces in buildings of various sizes and shapes. The foam is made up of polyurethane molecules that have been specifically formulated to provide excellent adhesion to concrete and protect it from cracking.

Without any specific parameter or size limit, this foam expansion polyurethane spray foam Insulation Liquid has the ability to fill gaps and cracks in concrete surfaces while maintaining its integrity and resistance to moisture and heat. It also has a high level of flexibility, which allows it to adapt to different types of concrete and apply consistently to each surface.

One of the key features of this foam is its ability to expand and contract over time as needed. This makes it suitable for use in complex construction projects where regular measurements and updates may become necessary. Additionally, the foam is resistant to leaks and contamination, making it an effective choice for use on building systems.

Overall, the Whole Building Concrete Crack Filler Expansion Polyurethane spray foam Insulation Liquid is an innovative and effective option for insulation applications in buildings of all sizes and shapes. With its versatile properties, high resilience, and adaptability, this foam can help improve the performance of your insulation system and ensure that your building stays secure and secure against moisture and temperature changes.

(Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam )

Company Profile

Foamed Concrete Services is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality concrete additives and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality concrete materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

Applications of Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam

Insulation and Filling: One of the primary applications of Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam is in insulation layers for roofs, floors, and walls. Its excellent thermal insulation properties help maintain interior temperatures, reducing energy consumption. Additionally, it’s ideal for filling voids, trenches, and abandoned pipelines due to its flowability and low density.

Lightweight Partition Walls: In residential and commercial construction, Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam is used to create non-load-bearing partition walls that provide both insulation and soundproofing, enhancing indoor comfort and privacy.

Concrete Slab Subbases: As a lightweight and self-leveling material, Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam serves as an ideal subbase for concrete slabs, reducing dead loads on structures and providing a stable, well-insulated base.

Foundation Stabilization: In soft soil conditions, Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam can be injected to stabilize foundations, prevent soil erosion, and mitigate the risk of subsidence, enhancing the overall stability of buildings.

Bridge Abutments and Embankments: Its lightweight property makes Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam suitable for backfilling bridge abutments and constructing lightweight barriers, reducing the load on structures and improving constructability.

Tunnel Lining and Mining: In tunnel construction and mining operations, Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam is utilized for tunnel linings and backfilling, providing stability insulation and reducing the risk of ground collapse.

FAQs of Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam

Q1:Is foam concrete strong enough for building construction?

A:Foam concrete, while not as strong as standard concrete, is versatile and can support certain loads. It is commonly used for a variety of non-structural elements such as partitions, insulation layers, and filler material, showcasing its adaptability in construction projects.

Q2:How does foam concrete compare in terms of cost to traditional concrete?

A:The cost of foam concrete, while comparable to regular concrete, can be slightly higher depending on factors like local prices, project specifics, and the need for specialized equipment. However, potential savings can be realized through reduced transportation and handling costs due to its light weight, making it a cost-effective alternative in certain situations.

Q3:Does foam concrete provide good insulation?

A:Yes, one of foam concrete’s key features is its excellent thermal insulation properties. Its porous structure minimizes heat transfer, making it highly effective for insulation purposes.

Q4:Can foam concrete be pumped or poured like regular concrete?

A:Absolutely; one of the advantages of foam concrete is its fluidity, which allows it to be easily pumped or poured into place, even in hard-to-reach areas or over long distances.

Q5:What exactly is foam concrete, and how is it made?

A:Foam concrete is a lightweight, porous material created by blending a cement-based mixture with stable foam or air bubbles. The foam is generated using a foaming agent and then introduced to the mortar or concrete mix, resulting in a low-density cellular structure.

(Whole Building Concrete Crack Filler Expansion Polyurethane Spray foam Insulating Liquid Polyurethane foam )